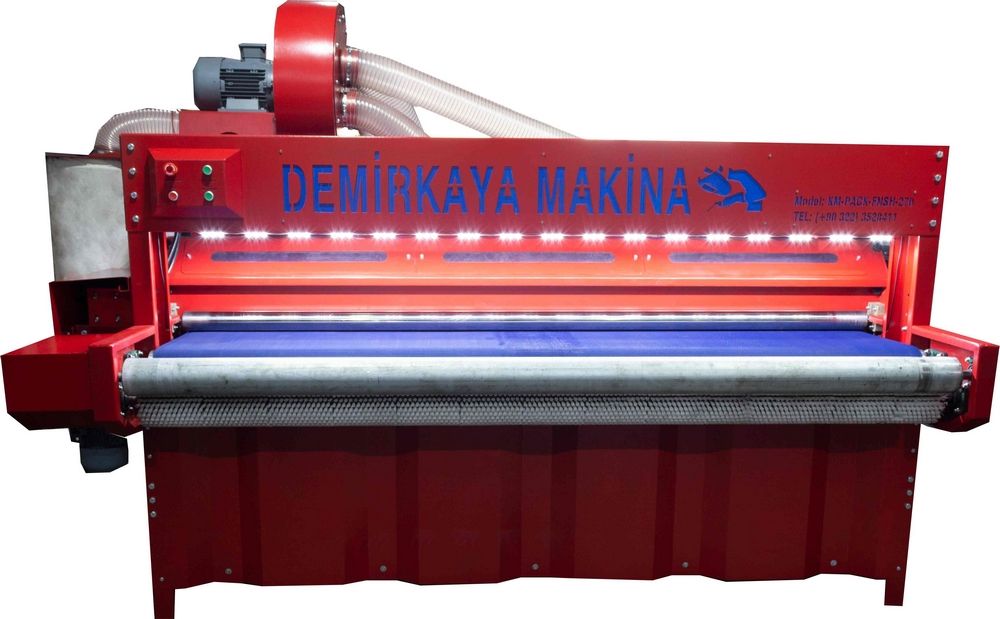

Carpet Packing Machine 270

DKM-PACK-FNSH-270

EXPLANATION

It is an industrial cleaning machine that will increase the quality of the sector and contribute greatly to businesses that want to become professional.

Tag: Carpet and Car Washing Machine, industrial carpet and car wash, Carpet Drying Machine Demirkaya Makina was established in Adana in 2008 and its fields of activity are car care and carpet washing services and machine production.

Carpet Packing Machine 270 Technical Data Overview

| TECHNICAL SPECIFICATIONS | DKM-PACK-FNSH-270 |

|---|---|

| Machine Model | DKM-PACK-FNSH-270 |

| Machine Carpet Scanning Length | 270cm |

| Roll Brush Diameter | 250mm |

| Machine Length | 330cm |

| Machine Height | 180cm |

| Machine Width | 180cm |

| Warranty Period | 2 Years |

| Foot System – Strong Chassis | √√ |

| Front and Rear Control Panel | √√ |

| Transport Size (cm) | 330x180x180 |

| Machine Model Year | 2020 |

| Machine Voltage | 380 Volt – 50 Hz |

| Special Dust Container – 90 Liter | Available |

| Packing Capacity (200-300 M2 / Hour) | √√ |

| Vacuum Engine | Available |

| Electricity Consumption | 6.5 Kwa/Hour |

| Band Forward and Backward Operation Button | Available |

| Top Roll Scanning Brush | 1 Piece |

| Bottom Roll Scanning Brush | 1 Piece |

| Weight | 900 Kg |

It is an industrial cleaning machine that will increase the quality of the sector and make a great contribution to businesses that want to become professional. Before or after the carpets are washed, the one that can pull the carpet inside the carpet also softens and combs the carpet hairs by combing. It is also a machine that you can do professionally for carpet packaging. There will be no need for the counters where the carpets in the enterprises are checked.

It is the last process performed before the delivery to the customer after the carpet has gone through the washing and drying processes. It is extremely comfortable to use our machine, which is used to clean the materials such as hair, fluff, bristle that will come and stick on the carpet during drying, to provide a beautiful appearance by combing the hairs of the carpet and to pack them. The banded system is activated when it sees the carpet thanks to the sensors located under our working machine. Thanks to the Band Adjustment system, the band system moves forward or backward. The hard roller brush at the top is movable up and down. The carpet is fed to the machine from the feeding point at the front with its feathers facing upwards. The roller system consisting of hard brushes descends down and scans the carpet. Thanks to the 1600 W vacuuming system, the unwanted substances collected by the brush accumulate in the outer bag. Carpets that have gone through the fluffing process are ready to be packed with the fluff free from all foreign matter, combed to the same side.